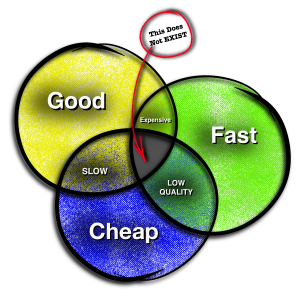

As mask makers, we often face the challenge of balancing quality, speed, and cost when fulfilling client orders. The Rule of Three, also known as the project management triangle or triple constraint, provides a helpful framework for navigating these trade-offs. The rule states that when creating a mask, you can only pick two out of the three options: good, fast, or cheap. Understanding and applying this rule can help us manage client expectations and ensure that we maintain the quality of our work while running a sustainable business.

As mask makers, we often face the challenge of balancing quality, speed, and cost when fulfilling client orders. The Rule of Three, also known as the project management triangle or triple constraint, provides a helpful framework for navigating these trade-offs. The rule states that when creating a mask, you can only pick two out of the three options: good, fast, or cheap. Understanding and applying this rule can help us manage client expectations and ensure that we maintain the quality of our work while running a sustainable business.

Good and Cheap: Not Fast

When a client wants high-quality masks at a low cost, the production timeline inevitably extends. This scenario often applies to custom or intricate designs that require meticulous attention to detail but must be kept within a limited budget. For instance, if a theater company commissions a series of masks for an upcoming play but has a tight budget, the mask maker might need more time to source affordable materials and invest additional hours into crafting each mask carefully. While the final product will be impressive and budget-friendly, the client must understand that the turnaround time will be longer.

Good and Fast: Not Cheap

On the other hand, if a client needs high-quality masks quickly, this will come at a premium price. Rush orders often require mask makers to prioritize these masks over others, possibly working extended hours or even hiring additional help to meet the deadline. For example, if a production company urgently needs a set of masks for a film shoot, the mask maker might need to purchase expensive materials and tools to expedite the process, thereby increasing the overall cost. The client will receive their high-quality masks on time, but they must be prepared to pay a higher price for the expedited service.

Cheap and Fast: Not Good

Lastly, if a client requires masks quickly and at a low cost, the quality will likely suffer. This situation is common for bulk orders where the emphasis is on quantity over quality. For example, if a school needs a large number of masks for a play on a limited budget and short notice, the mask maker might use less expensive materials and simplify the design process to meet the requirements. While the masks will be affordable and delivered quickly, they may lack the fine craftsmanship and durability of higher-quality options.

Navigating Multiple Mask Orders

The Rule of Three becomes even more critical when dealing with multiple mask orders. For single custom orders, managing client expectations around the Rule of Three is relatively straightforward. However, for bulk orders or ongoing projects, mask makers need to carefully plan their workflow and resources to balance these trade-offs effectively. Communicating clearly with clients about the limitations and possibilities within their budget and timeline helps ensure that everyone is on the same page.

By embracing the wisdom of the Rule of Three, mask makers can make informed decisions, set realistic client expectations, and maintain the integrity of their craft. As we continue our creative journey, let’s use this valuable tool to thrive and stay alive in the vibrant world of mask making.